Many people are confused when they first heard about VPI transformers. Do you not know what this is?

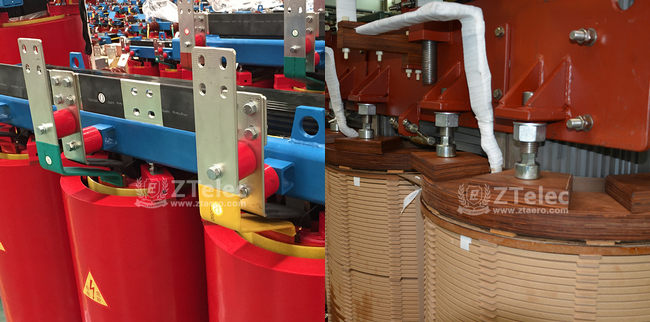

The VPI transformer is an abbreviation of Vacuum Pressure Impregnating Transformer and represents a manufacturing process. It is equivalent to dividing yellow people into Chinese and North Koreans, and the basis for classification is different. This is also true of VPI transformers, which are dry-type transformers. Because there is vacuum pressure in the manufacturing process to immerse this part, it is called the Vacuum Pressure Impregnating transformer.

So what is VPI transformer manufacturing process?

Vacuum pressure impregnation equipment is an important process equipment in the production process of electrical and electrical materials such as high-voltage motors, transformers, power capacitors and paper-insulated high-voltage power cables. Its working principle is to pre-bake the workpiece after cooling, placed in a vacuum environment Remove the air and volatiles inside the blank coil, rely on the gravity of the paint in the vacuum and the capillary action of the coil, and use dry compressed air or inert gas to apply a certain pressure on the impregnated paint after the vacuum is released to make the paint Rapidly infiltrate and fill the inner layer of the insulating structure to achieve the purpose of impregnation.

What are the advantages of vacuum pressure pre-immersion?

After being processed by VPI process, the insulation performance is good, the temperature rise is reduced, the efficiency is increased, the mechanical strength is increased, the loosening phenomenon of the operation process is solved, the insulation fault such as a short circuit is prevented, the moisture resistance is improved, and the service life is prolonged.

ZTELEC VPI transformers are of good quality and low price.