What is Electrical Laminated Wood Board?

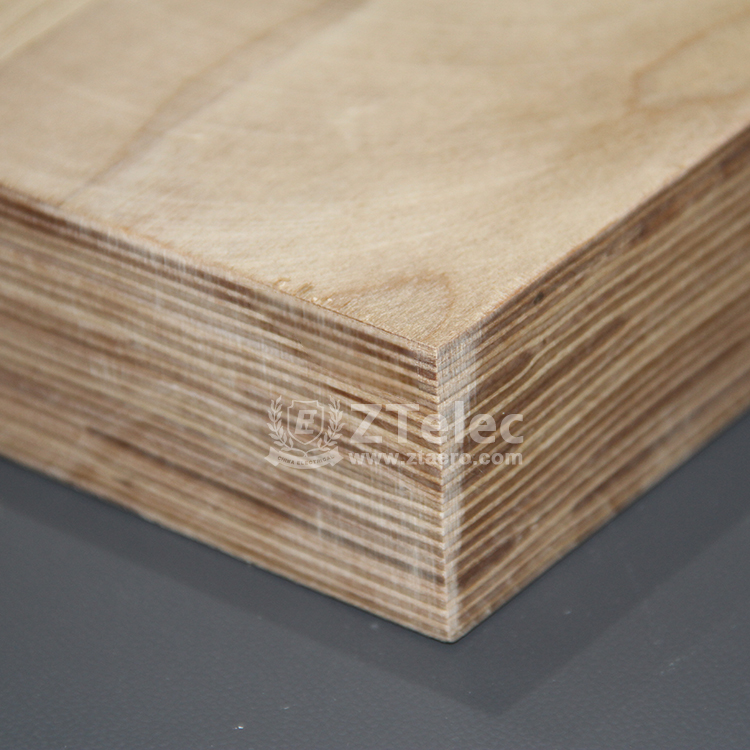

Electrical Laminated Wood Board is a veneer made of high-quality wood which is cooked, rotary-cut and dried. It is coated with special insulating glue and is made of high-temperature pressed plate material. It is a wood-based panel.

How is laminated plywood made?

The qualified substrate is selected, subjected to one soaking, subjected to secondary soaking, and then spirally cut, and then the board is dried, then the board is cut and repaired, glued and assembled, pre-pressed, and finally hot pressed. (Using low-media adhesive, several layers of veneers, each layer of veneer is 1.2-2.2mm thick, criss-crossed by wood grain, crisscross, parallel parison, high pressure pressing.)

What is the purpose of laminated wood?

Widely used in insulation and support materials in transformers and transformers. It has the advantages of moderate specific gravity, high mechanical strength, easy vacuum drying and easy machining. Its dielectric constant is close to that of transformer oil, and its insulation is reasonable. It can be used for a long time in transformer oil of 105 °C. Electrically laminated wood boards have been widely used in oil-immersed transformers to manufacture upper and lower pressure plates, lead supports, iron yoke pads and other parts. They are used to make clamps in transformers, which replace steel plates, insulating paperboards, and epoxy paperboards. Epoxy glass cloth board in these applications, thereby reducing the transformer's own weight and material costs

Parameter

| Standards: GB/T 20634.3-2008 /IEC61061-2:1998 | ||||||||

| NO. | Properties | Unit | Index | |||||

| DLW101 | DLW201 | DLW202 | DLW301 | |||||

| 1 | Appearance | - | Smooth Surface, Neat Edge Cutting, No Layered Cross-section |

|||||

| 2 | Density | g/cm³ | 1.2-1.3 | 1.1-1.2 | 1.1-1.2 | 1.0-1.1 | ||

| 3 | Vertical Bending Strength |

A Direction | MPa | ≥80 | ≥65 | ≥65 | ≥55 | |

| B Direction | ≥80 | ≥65 | ≥65 | ≥55 | ||||

| 4 | Impact Strength | A Direction | KJ/m2 | ≥15 | ≥13 | ≥13 | ≥10 | |

| B Direction | ≥15 | ≥13 | ≥13 | ≥10 | ||||

| 5 | Interlaminar Shear Strength |

MPa | ≥9 | ≥8 | ≥8 | ≥7 | ||

| 6 | Vertical Electrical Strength (90℃ transformer oil) |

Kv/mm | ≥9 | ≥8 | ≥7 | ≥7 | ||

| 7 | Parallel Breakdown Voltage (90℃ transformer oil) |

kv | ≥50 | ≥50 | ≥50 | ≥50 | ||

| 8 | Contamination to Liquid Dielectric |

- | ≤0.1 | |||||

| 9 | Shrinkage after Drying |

A Direction | % | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.3 | |

| B Direction | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.3 | ||||

| Thickness Direction | ≤3 | ≤3 | ≤3 | ≤3 | ||||

| 10 | Water Content | % | ≤6 | ≤6 | ≤6 | ≤6 | ||

| 11 | Oil Absorption | % | ≥5 | ≥8 | ≥8 | ≥10 | ||

| Application Scope of Laminated Wood Insulating Parts used for Transformer |

Transformer Rating | ≥ 110KV | ≤110KV | 66-35KV | ≤ 35KV | |||

Note:The data in the above table only represents typical or average data, just for reference in practical application. It does not bear any responsibility for the use of the product or related legal liability.

Package&Storage: Wrapped with packaging film and packed in pallet; horizontally placed in dry and clean room at room temperature; keep it away from moisture and fire. The storage period is 12 months.