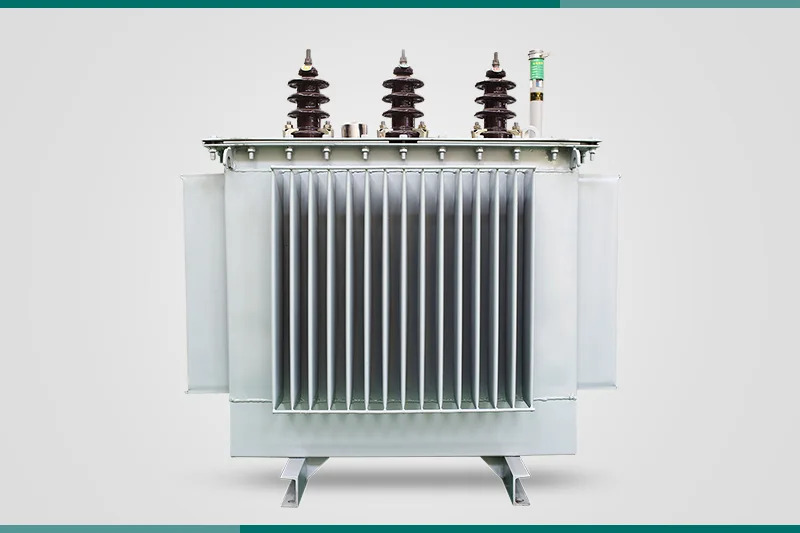

The S11 oil-immersed transformer mainly consists of the following parts: core, windings, oil tank, insulating oil, cooling equipment, and ancillary devices.

Core: The core of the S11 transformer is usually made from high-quality silicon steel sheets, subjected to strict processing techniques to enhance its magnetic flux density and reduce losses. The core design uses an interleaved structure aimed at minimizing leakage flux and improving transformer efficiency.

Winding: The windings are the main functional components of the transformer, divided into high-voltage and low-voltage windings. To ensure efficient power transmission, winding materials are generally made of copper or aluminum, which possess excellent conductive properties and undergo insulation treatment to ensure safety and reliability.

Oil Tank: The oil tank serves as the outer shell of the S11 transformer, constructed from high-quality steel plates welded together. It not only provides good sealing and mechanical strength but also serves as a key medium for heat dissipation.

Insulating Oil: The insulating oil filled inside the transformer has excellent insulation and heat dissipation properties, effectively protecting the windings and core, preventing moisture ingress, and lowering temperature.

Cooling Equipment: To ensure efficient operation of the transformer, the S11 oil-immersed transformer is equipped with either natural cooling or forced oil circulation cooling systems, which significantly enhance heat dissipation performance, ensuring safe and stable operation under various working conditions.

Ancillary Devices: Monitoring devices such as thermometers, pressure gauges, and oil level indicators ensure the safe operation of the transformer and allow real-time monitoring of its operating status.

S11 Oil-Immersed Transformer Product Advantages:

The S11 oil-immersed transformer has several significant advantages compared to other types of transformers:

High Efficiency and Stability: Its design employs more advanced materials and processes, effectively reducing no-load losses and load losses, thus enhancing energy conversion efficiency.

Excellent Heat Dissipation Performance: The oil-immersed design allows for effective heat dissipation during operation, maintaining a stable temperature for the equipment, thereby increasing reliability and service life.

Good Insulation Performance: The insulating oil used possesses excellent insulation properties, maintaining superior insulating characteristics under high voltage conditions, thereby reducing risks of short circuits and leakage.

Strong Adaptability: The structural design offers strong adaptability, enabling stable operation in various environments, especially suitable for extreme conditions such as high temperatures, high humidity, and dusty environments.

Low Maintenance Costs: Due to its simple and reliable construction, the S11 oil-immersed transformer has lower maintenance costs and longer maintenance intervals, reducing subsequent investments for users.

S11 Oil-Immersed Transformer Application Scope:

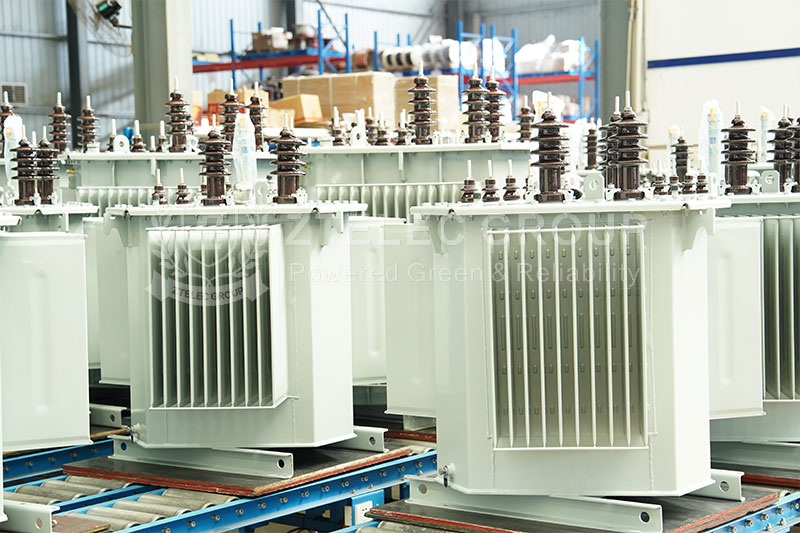

The S11 oil-immersed transformer is widely used in various power systems and industrial locations, including but not limited to:

Electric Power Substations: As an essential power conversion device, S11 transformers are utilized for voltage transformation and power distribution, widely applied in various high-voltage and low-voltage substations.

Industrial Enterprises: In heavy industries, chemical industries, metallurgy, and other sectors, the demand for electricity is significant due to high-power equipment. The S11 oil-immersed transformer can provide a stable power supply for these enterprises.

Residential Areas: To meet the daily electricity needs of residents, S11 transformers are also widely applied in low-voltage distribution networks, ensuring the safety and stability of household electricity.

Renewable Energy: In renewable energy systems such as solar energy and wind energy, S11 transformers can connect the electricity generated by power generation equipment to the grid, optimizing energy allocation and utilization.

The working principle of the S11 oil-immersed transformer is based on the law of electromagnetic induction. When alternating voltage is applied to the high-voltage winding of the transformer, an alternating magnetic field is generated within the winding. This magnetic field is coupled to the low-voltage winding through the core, inducing a corresponding alternating voltage in the low-voltage winding. The voltage transformation ratio depends on the turns ratio between the high-voltage and low-voltage windings. After connecting to the power source, the insulating oil in the oil tank circulates naturally or is pumped, removing the heat generated by the windings and core, ensuring stable operation within a safe temperature range.

the S11 oil-immersed transformer, with its unique product structure, significant advantages, wide application range, and orderly working principle, has become an indispensable piece of equipment in modern power systems. With continuous technological advancements, the application of S11 transformers in the power sector will become even more prevalent, laying a solid foundation for achieving more efficient and safer power transmission and distribution.

Leave A Comment