What is a transformer?

Transformer is a device that uses the principle of electromagnetic induction to realize power transmission. It mainly consists of core, winding, insulation material and shell. The iron core is one of the main components of the transformer. In addition to supporting and fixing the windings, the iron core can also gather magnetic field lines between the windings, thereby improving the efficiency of power transmission. The winding is the most basic electrical component in a transformer. It is composed of wires and can be used to transmit electrical energy. Insulating material is used to isolate the electric field between the winding and the casing to avoid electrical breakdown. The outer shell of the transformer mainly plays the role of protection and isolation.

How to cool a transformer at high temperatures?

No transformer is truly an “ideal transformer” and hence each will incur some losses, most of which get converted into heat. If this heat is not dissipated properly, the excess temperature in transformer may cause serious problems like insulation failure. It is obvious that transformer needs a cooling system. Transformers can be divided in two types as (i) dry type transformers and (ii) oil immersed transformers.

Dry-type transformers, are normally cooled by air. The following two transformer cooling methods are adopted in dry-type transformers.

Air Natural cooling (AN) – Cooled by surrounding air. Heat transfer by natural air convection.

Air Force cooling (AF) – Forced air circulation using fans and blowers.

Oil-type transformers are cooled using oil-air cooling or oil-water cooling method. There is a wider range of cooling methods for oil-type transformers.

(Mineral) Oil Natural Air Natural (ONAN) – The core and coils are cooled by surrounding in oil. Heat transfer of oil by natural air convection.

(Non-Mineral) Oil Natural Air Natural (KNAN) – The core and coils are cooled by surrounding in synthetic oil. Heat transfer of oil by natural air convection.

Oil Natural Air Forced (ONAF) – Cooled by surrounding in oil. Forced air circulation using pumps, fans and blowers.

Oil Forced Air Forced (OFAF) – Forced oil and air circulation using fans and blowers.

Oil atural Water Forced (ONWF) – Cooled by surrounding in oil. Forced water circulation using heat exchanges.

Oil Forced Water Forced (OFWF) – Forced oil and water circulation using oil-to-water heat exchanges.

What is a transformer cooling class?

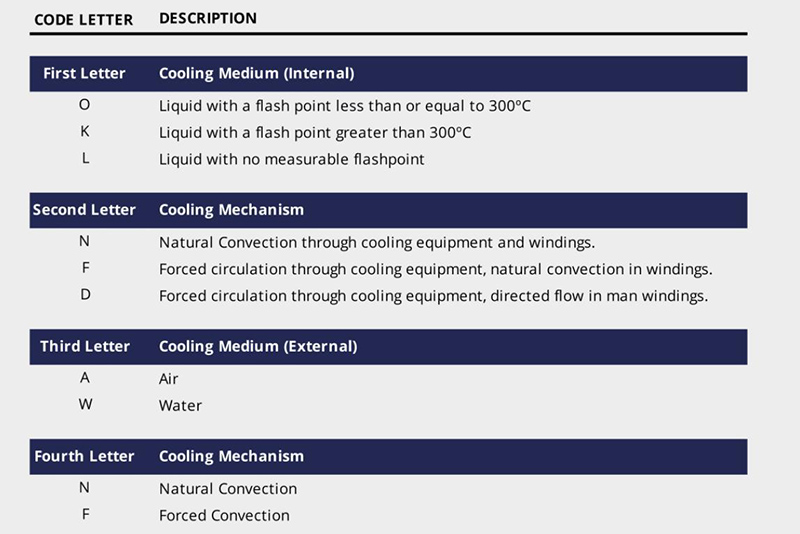

A transformer cooling class defines the method and efficiency with which a transformer dissipates the heat generated during its operation. This classification is crucial as it determines how the transformer handles thermal stress and maintains its performance under varying electrical loads. Each cooling class is designated by a series of letters such as ONAN (Oil Natural Air Natural), OFAF (Oil Forced Air Forced), and others, which detail the type of coolants used (oil, air, water, gas) and whether the circulation is natural or forced. Understanding these classes helps in selecting the right transformer for specific applications, ensuring that it operates within its thermal limits.Transformer cooling class letter descriptions:

What is the significance of transformer cooling class?

By choosing the appropriate cooling class, operators can ensure that transformers do not overheat and degrade prematurely, which is crucial in maintaining system reliability and reducing downtime. Moreover, the cooling class affects the physical size, installation environment, and cost of maintenance of the transformer, making it a key consideration in the design and operational planning of power distribution systems. This careful selection helps in achieving optimal performance and durability, tailored to specific environmental conditions and load requirements.

Leave A Comment